Pro

Power Meets Precision for Mid-Sized Operators -

Dominate Output. Keep the Crew Lean.

Up to 24,624 Cones Per Day

Built by Operators, for Operators.

Achieve 30% Higher Output with Pro Component Upgrades & Enhanced Assembly Line Workflow.

Ready to Scale Rapidly? The Pro Package is Your Accelerator.

The Ultra-Reliable Pro Package. This workhorse setup efficiently produces over 24,600 consistent, perfectly finished pre-rolls per day with a lean team of 2-3 operators. Future-proof your production with our simple and cost-effective upgrades.

FlexPak Max Pro Package reviews

Pro Clients Share Experience

"...A Huge Boost In Our Business Growth"

"While the FlexPak Max is an absolute power-house of a joint machine. What really sets it apart is the FlexPak team. Any time we have a question...they're there for us." - Stacy K.

"100% Getting A Second Machine!"

"We ended up getting the Premium package and after three months we were so happy we upgraded to the Pro package... " - Marcel V.

package details & pricing

Pro Package

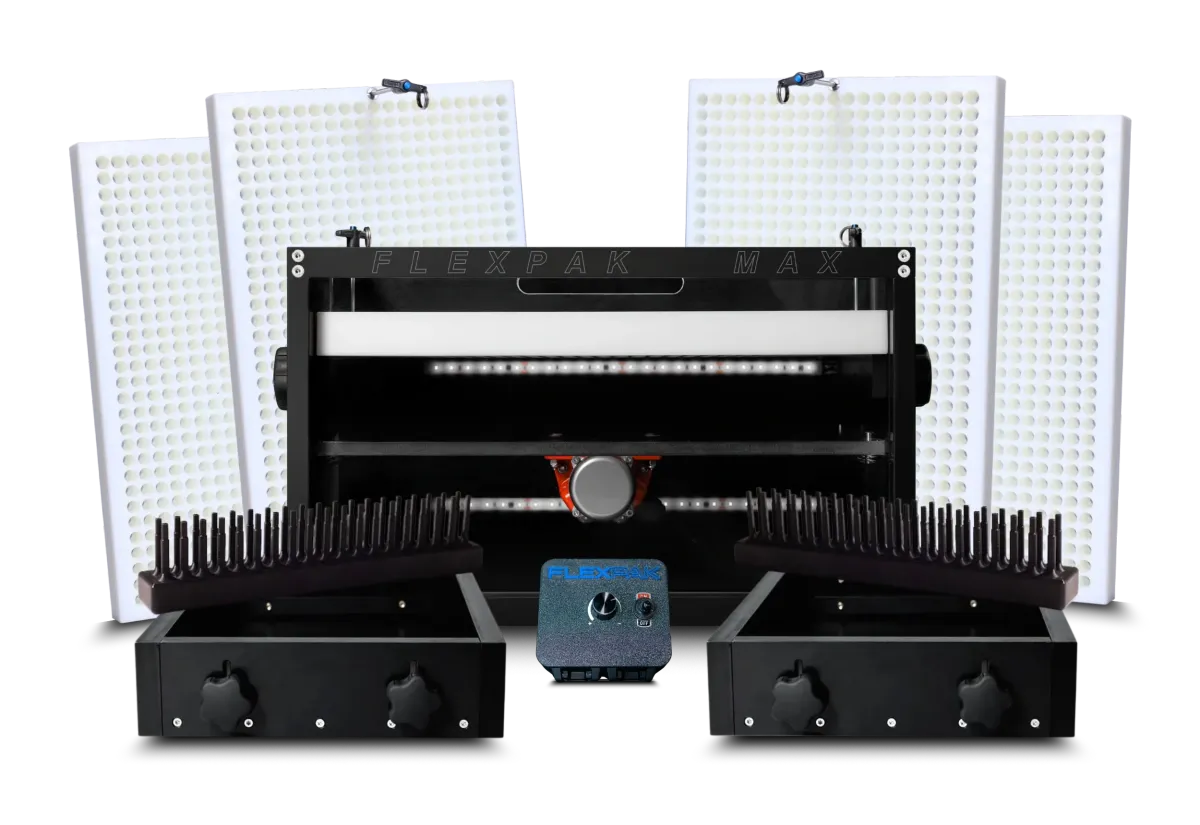

FlexPak Max Pro Package

Lifetime Support

Package Includes:

FlexPak Max Machine

(4) Cone Plates of your choice

(2) Setup Boxes

(2) Standard Crowning / Closing Tools

Assembly Workflow SOP's

Lifetime Support (Machine & Production)

One Year Mechanical & Electrical Warranty

Unmatched total value compared to similar packages from leading competitors:

$58,400.00+

Pro Package: $17,400.00

"We recently moved up to the Pro Package - it was streamlined and very cost effective!"

- Green Rocket

Proven FlexPak Max Solutions

Concerned about future growth limiting your initial machine purchase?

Start Producing Fast, Scale Effortlessly. The FlexPak Max Pro Package gets your operation running quickly. When it's time to grow, simply add to your current setup to double your output — no need for a complete system overhaul. It's designed to expand with your business, saving you significant investment as you scale.

Your tired of or don't want to waste money on an unreliable pre-roll system?

Engineered for Unwavering Performance and Minimal Downtime. While other machines may struggle under pressure, the FlexPak Max utilizes high-quality materials and a robust design built for heavy commercial operation. Expect consistent output and avoid costly interruptions with a system engineered for 10+ years of reliable service.

Efficiency suffers due to inconsistent weights and excessive touchpoints.

Eliminate Weight Issues & Bottlenecks with Flex Metering for Consistent Flow & Higher Profits. Our tech dynamically adjusts to material, density, and humidity, ensuring precise weights and minimizing production halts. Fewer manual checks mean lower labor costs and increased output.

Say Goodbye to Unreliable Machines and Hello to Scalable Growth. The FlexPak Max is specifically designed to resolve those pain points and drive your success.

Got questions?

Book your pre-demo call and personalized consult now.

Compare the Packages.

Crunch the numbers with the ROI calculator.

| Packages | Premium | Pro | Enterprise |

|---|---|---|---|

| Package Cost | $14,350.00 | $17,400.00 | $34,800.00 |

| Production Capacity | |||

| Staff Needed | 1-2 people | 2-3 people | 4-6 people |

| Production Rate | 4 plates/hr | 6 plates/hr | 12 plates/hr |

| Daily Capacity | Up to 16,416 cones | Up to 24,624 cones | Up to 49,248 cones |

| Package Includes | |||

| FlexPak Max Machine | 1 | 1 | 2 |

| Cone Plates | 2 of your choice in size | 4 of your choice in size | 8 of your choice in size |

| Setup Boxes | 1 | 2 | 4 |

| Standard Closing Tools | 1 | 2 | 4 |

| Assembly Workflow SOP's | |||

| Lifetime Support | |||

FlexPak Max Package ROI Calculator

This calculator provides estimates based on the inputs selected. Actual results may vary.

FlexPak Max

Pro Package

Features & Benefits

Built Different

Features

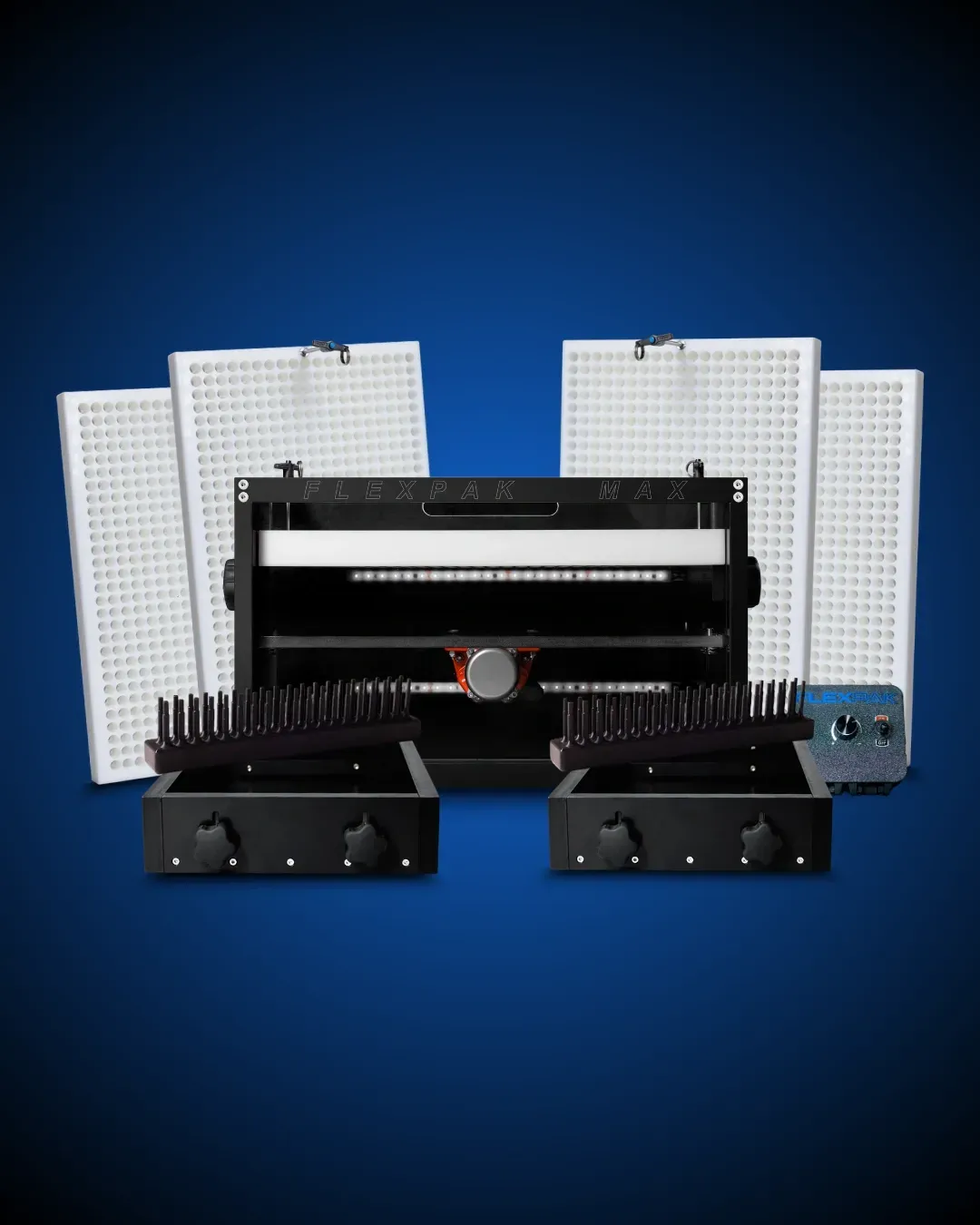

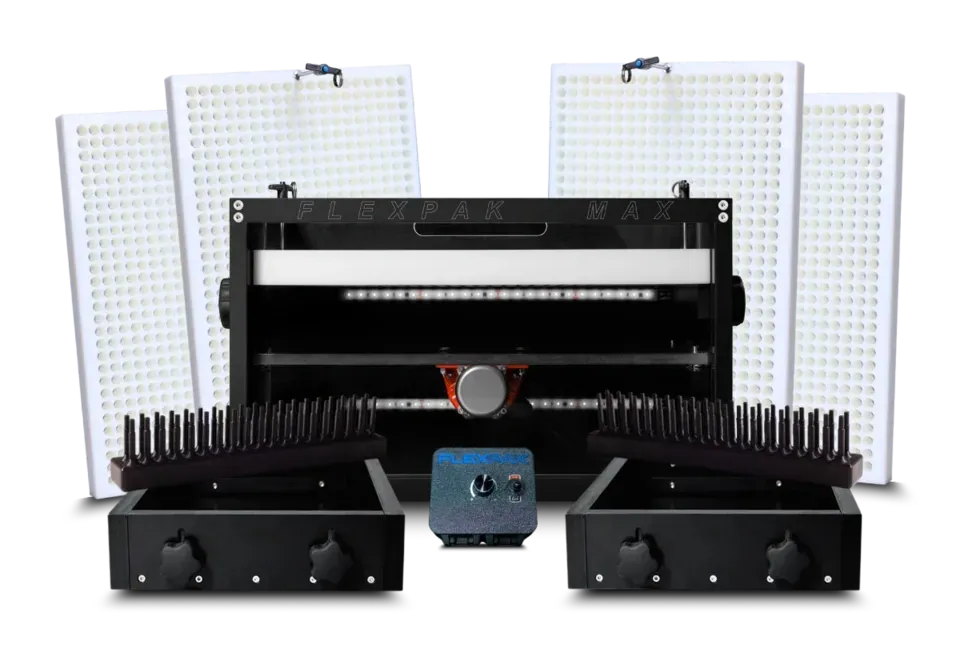

FlexPak Max Machine Core

This is serious machinery. Proudly engineered and built in our Oklahoma facility, each unit utilizes premium, locally sourced materials. From the aircraft-grade T-6 aluminum frame with its refined black anodized finish to the enduring stainless steel components and smooth Lexan vibration plates, this machine is built for lasting performance and a professional aesthetic. Dual high-output LED strip lights provide exceptional interior illumination, ensuring uncompromising precision in every operation.

Machine Dimensions:

20 3/4"L x 15" W x 12.5" H

Weight w/ Motor:

60 lbs.

Industrial Strength Motor

Engineered for High-Volume Production: Our Heavy-Duty Vibrating Motor. This robust 120V 3-phase industrial motor delivers a consistent 50 watts of unwavering power, specifically designed for the demands of continuous pre-roll production. Built for longevity, it provides dependable, rock-solid performance with an expected lifespan of 8 to 10 years, ensuring your operations run smoothly and reliably, batch after batch.

Max Cone Plates

Precision-Engineered FlexPak Cone Plates: Crafted in Oklahoma for Uncompromising Results. Machined in-house from durable, food-grade HDPE, each plate features a precision taper designed for flawless packing of 513 cones with exceptional speed and accuracy. Engineered to exceed industry standards, our plates are available in 70mm, 84mm, 98mm, and 109mm sizes. Need a custom specification? We're ready to deliver. Each plate provides a substantial 7 lbs of production-grade stability to your workflow.

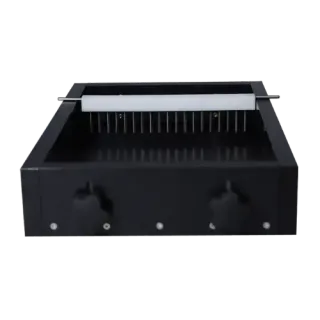

Closing Tool & Set-Up Box

Optimize Your Finishing Process with the FlexPak Crowning Tool / Joint Closer. Designed to accelerate your workflow and eliminate inconsistent finishes, this tool ensures a clean and professional final product. Paired with our robust Setup Box, constructed from food-grade HDPE and reinforced with steel, for a durable and reliable prep station that streamlines cone preparation, keeping it fast, clean, and consistent—engineered to withstand the demands of high-volume production.

Motor Controller

Achieve Total Command and Flawless Packing. Our industrial-grade Motor Controller provides the precise power you need, with a clean 120V input and a stable 120V 3-phase output for your vibrating motor. Fine-tune speed and force to optimize efficiency and ensure uncompromising packing consistency. Engineered for high-demand environments and lasting performance, this controller keeps your production accurate, stable, and perfectly calibrated.

Benefits

Durable Design, 10+ Year Lifespan

Engineered for a Decade of Relentless High-Volume Production. The FLEXPAK MAX is built for enduring performance. Constructed with premium materials, including aircraft-grade T-6 aluminum, stainless steel components, and durable Lexan vibration plates, it's designed to be your long-term, dependable production workhorse. Powered by a precise motor controller and illuminated by dual LED strips, it delivers consistent and efficient operation, shift after shift, year after year.

Open Design = Easy Clean & Maintenance

Experience a Smarter Design: Open, Accessible, and Easy to Maintain. Unlike overly complex, sealed machines, the FlexPak MAX features an open and accessible layout, simplifying cleaning, minimizing material waste, and ensuring straightforward maintenance. With no hidden components or unnecessary complexity, its intelligent engineering allows for easy disassembly, thorough cleaning, and quick reassembly, keeping your production consistent and your quality impeccable.

Optimal Output, Unbeatable Cost-Efficiency

Maximize Your Output and Minimize Your Costs. The FLEXPAK MAX delivers an unmatched number of filled and sealed cones per dollar. With industry-leading output, minimal maintenance requirements, and seamless operation, it's engineered to exceed your production goals while significantly reducing expenses. Achieve higher volumes, simplify your operations, and boost your profitability. If expansion is your focus, this machine is your catalyst for growth.

Dial In Perfect Precision with Flex Metering

Experience Real-Time Control with Flex Metering: Adaptability at Your Fingertips. Move beyond outdated tray systems. Our Flex Metering setup provides complete, real-time command over your filling process. Designed to handle diverse grades, grinds, and strains effortlessly, its adjustable upper rails allow for precise calibration of cone plate fill levels. Achieve your target weights consistently, minimize material waste, and ensure cleaner, superior fills. That's the FlexPak advantage in action.

Streamlined Assembly Workflow & Dedicated Support

More Than Just a Machine: We Provide the Blueprint for Success. Through years of dedicated refinement, we've developed an assembly line workflow that maximizes output and eliminates production bottlenecks. From initial cone loading to final closing, every stage is optimized for peak efficiency—and this proven system is yours. Beyond the machinery, our support team comprises seasoned pre-roll professionals with real-world experience. From troubleshooting technical issues to fine-tuning your processes, we offer practical solutions, not just theoretical advice. Efficient systems, expert guidance, and guaranteed results—eliminate the guesswork.

TESTIMONIALS

What Our Clients Have to Say

"The FlexPak Max is a game-changer! Super easy to use, incredibly durable, and packs perfect weights every time. The closing tool is flawless—perfect dutch crowns. Scaling up production has never been smoother. Highly recommend for anyone serious about quality and efficiency!"

Area 52 Farms

"Love this machine! The FlexPak Max delivers consistent, tight rolls with zero guesswork. The closing tool works like magic, and setup is a breeze. Built to last and perfect for growing businesses. Worth every penny!"

Ox Distribution

"Best preroll machine we’ve used! The FlexPak Max is reliable, fast, and produces perfectly weighted cones every time. The closing tool seals them flawlessly. Easy to operate and built like a tank. A must-have for scaling production without sacrificing quality!"

Premium Agriculture

Experience the FlexPak Max Difference

Experience the FlexPak Max power through 513 Joints in a quick Live Stream Demo.

Forget the Pitch See the Proof.

FlexPak Max Packages

Need Less or More Production?

Check Our Other Packages

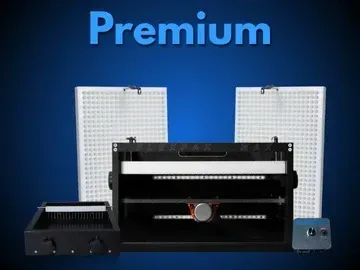

Up to 16,416 Pre-Rolls Per Day

Premium

FlexPak Max Machine

(2) Cone Plates of your Choice

(1) Setup Box

(1) Standard Crowning Tool

Assembly Line Blueprint / Proven SOP's

Lifetime Support / Troubleshooting

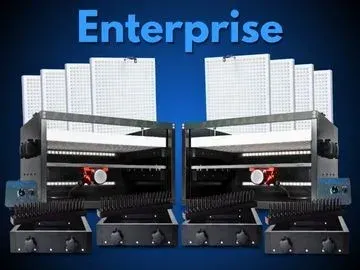

Up to 49,248 Pre-Rolls Per Day

Enterprise

(2) FlexPak Max Machine

(8) Cone Plates of your Choice

(4) Setup Boxes

(4) Standard Crowning Tools

Assembly Line Blueprint / Proven SOP's

Lifetime Support / Troubleshooting

FlexPak Black Glove Set-Up

FlexPak Production Team

Onsite Set-Up & Manufacturing Consultation

Comprehensive Onsite Staff Training

FlexPak Team Does Full Production Run With Staff

* Limited Add-On Package - Contact For Details

Direct Comparison

VS

Futurola Knockbox 500 &

STM Rocketbox 2.0

| FEATURES | FLEXPAK MAX |

FUTUROLA KNOCKBOX 500 |

STM ROCKETBOX 2.0 |

|---|---|---|---|

| Pricing | $14,350.00 | $24,998.75 | $24,950.00 |

| Cone Capacity | 513 CONES | 500 CONES | 453 CONES |

| Set-Up Box | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Cone Loader & Unloader | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Joint Closing Tool | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Lift Plate / Metering Adjustment | ✓ | ✗ Additional Cost | ✓ |

| Maintenance / No Tech Needed | ✓ | ✗ | ✗ |

| Manufactured in USA | ✓ | ✗ | ✓ |

Frequently Asked Questions

Pro Tier FAQ's

When is it time to become a Pro with the FlexPak Max?

The best time to purchase this package is if you have more experience in cones and you know what you need to get out of your machinery. You may not be in need for multiple machines yet, but you have a growing business.

How quickly will the machine pay for itself?

ROI was a huge factor for us in designing this machine, that is a main reason we made it to do 513 cones at a time. Example, if you sell your cones for only $1 each, the machine technically generated enough revenue to pay for itself on the first day. You will see in the package that the price is very close to how many cones you can produce in a day, we did that on purpose.

How do I maximize what this package can do?

We offer SOP’s from our manufacturing as well as them from operations at significantly higher volumes than we did. We believe if you don’t try and reinvent the wheel and you buy into the process, the machine will naturally be operating at its potential.

How does your price compare to other machines in the market?

The FlexPak Max cone-filling machine and crowning (joint closing) process is so well priced that the machine will pay for itself within the first 30 days of use, if not sooner. To get an equivalent setup (packing machine and crowning setup) from the closest competitor you’d have to pay $50k-$55k.

What differentiates FlexPak from other Pre-Roll Machine Companies?

Flexpak Inc. was formed by a group of manufacturers that designed a machine to fit their business, through that we’ve solved problems that other machines haven’t, and have produced a machine that does what it is designed to do plus more.

Any type of warranty?

We offer a bumper to bumper One (1) year warranty on the FlexPak Max, we also maintain stock of any wearable items that are easily and cheaply replaced when needed.

Customer Service?

Customer service in this industry, especially on the machinery side is lackluster at best. How we keep our customers happy after purchasing is we have a team designated for zoom demos, questions, tips, pointers, etc. We even offer a lot of information about different areas of the pre-roll process that can also help ensure you're getting the best results possible. There are a ton of factors that go into making a quality pre-roll other than the machinery working as it should.

How much volume can we expect out of the machine?

We usually take a consultative approach and work with you in depth to make sure you get what you need out of your particular setup. We offer three main packages: Premium Package: Up to 16,416+ cones/day (1-2 operators), Pro Package: Up to 24,624+ cones/day (2-3 operators) and the Enterprise Package: Up to 49,248+ cones/day (4-6 operators).

How easily will my team learn this process coming from using different machinery?

The FlexPakMax was designed specifically for efficiency and simplicity. We have customers that come from all different backgrounds and machinery that implement this process smoothly and quickly.

How fast can I receive my setup?

We manufacture these 100% at our facility in Oklahoma, we maintain a good stock of inventory and usually ship within 48 hours of purchase. This however, can vary depending on the order quantity and specifics.

Pre-demo call & consult

Unsure Which Package is Best?

Schedule a quick call to discuss your requirements and receive a thorough consultation focused on solutions, not sales.

Book your pre-demo call & consult today!